The Volcano

Bishop Museum, Hawaii

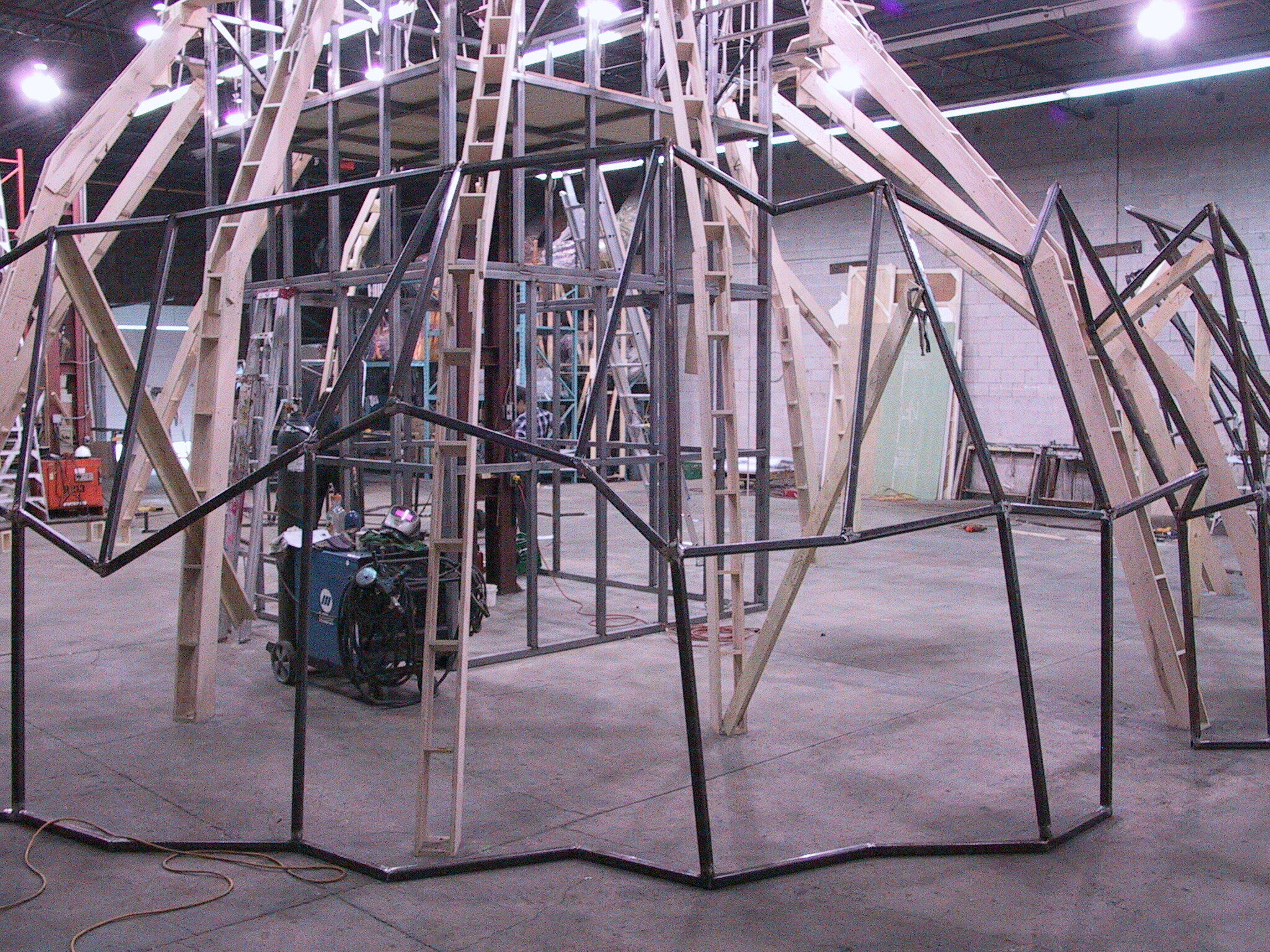

Volcano assembly and installation, Bishop Museum Hawaii

The volcano was a tremendously complex project, involving the coordination of many trades, subcontractors, and designers. By the time we became involved, there was only about 6 months left in the schedule to build the giant structure, ship it to Hawaii and install it.

Measuring approximately 40 feet diameter at the bottom and about 22 feet tall, the volcano was designed as a sculptural metal frame clad with an aluminum “skin”. We were contracted to do the sculptural part — the skin and the frame — which needed to be installed on top of an engineered super-structure by others. There was also a lava effect by others and interior exhibits by others, plus it had to be installed in and around the new building which was also under construction.

The drawing package we received was extensive but the volcano was so big and such a weird shape that it was really hard to visualize it in 2D. We knew the only way to get a real sense of what we were building was to see it in 3D, so we built a model first, complete will all the structures that it needed to fit in and on.

We also knew we had to build the entire structure in the shop. There was no other way. It would have to be pieced back together like a puzzle on site. So we made our own superstructure just like the real one and laid out the exact floor plan from the drawings and built it from the ground up.

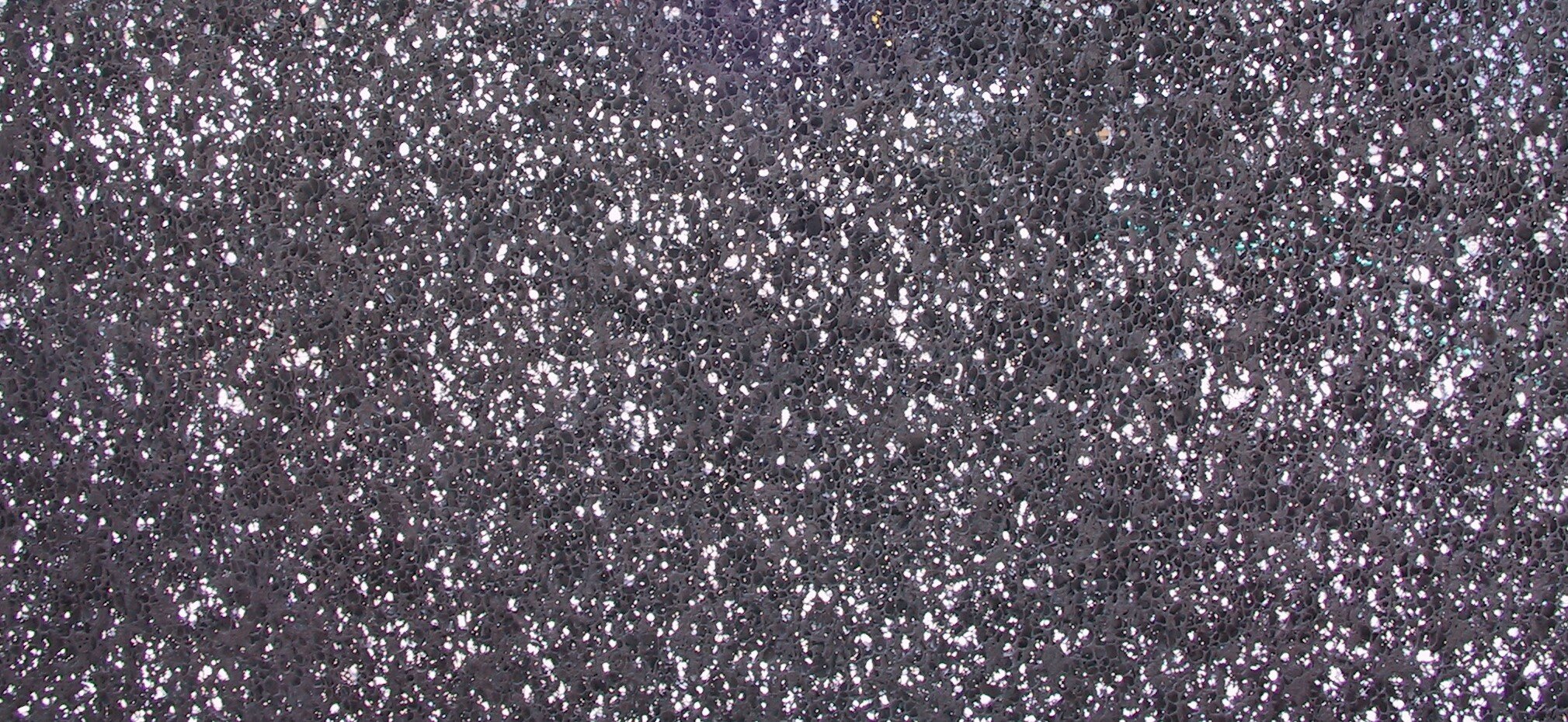

Close-up of Alusion, the product specified for the skin of the volcano.

The architect has specified an architectural panel called Alusion for the skin. Described by the manufacturer as “cellular cast aluminum foam”, Alusion was intended for ceiling or wall panels and was only made by one company in the whole world.

Since we couldn’t weld the Alusion to itself or to our steel frame, or use fasteners, we had to figure out a way to attach the skin to the frame. We researched construction-grade adhesives and found a super-strong glue that would bond the Alusion to the frame and to itself.

As we were cutting and assembling the panels for the skin, handling the panels was tricky, because the edges were so sharp, and we realized that it was potentially dangerous to the public.

The solution was to find some kind of coating that would cover the surface of the skin all the way around the bottom of the volcano up to a touchable height of about 8 feet. We started researching again and found a coating that would preserve the look of the ALusion, both in colour and density, met fire code, and had the right texture to make the surface soft to touch.